Typical oil sludge is coming from: Sources generally are:

- Normal Production Operations

- Tank Bottom Sludge

- Skimmed Oil

- Pigging Operation

- Workover Spills, etc.

Oily Sludge Major Problems:

- A Hazardous Waste.

- Serious threat to ground water.

- Difficult to separate constituents and meet the targeted KPIs (BS&W).

- Occupies the Tank Volume and ollutes the clear fluid.

Commercial Loss :

Loss of VALUABLE PRODUCT which can be recovered by our method.

Low Steam Processing Unit: A Solution for Oil Sludge Treatment

The low steam processing unit (LSPU) is a valuable tool for effectively treating sludge. By introducing hot steam into the sludge treatment tank, it significantly reduces the viscosity of the sludge, making it more mobile and easier to process. This increased fluidity also aids in breaking down emulsions, facilitating the separation of oil and water. The LSPU offers a practical and efficient solution for improving sludge management and environmental sustainability.

Lagoon/Pond Cleaning:

BIGGER SIZE ROBOT NAMED GAJANAN – 1.0

Chemical & equipments

Patented Chemicals Sludge Treat and Slop Treat are used for operation.

ARSC31 Sludge

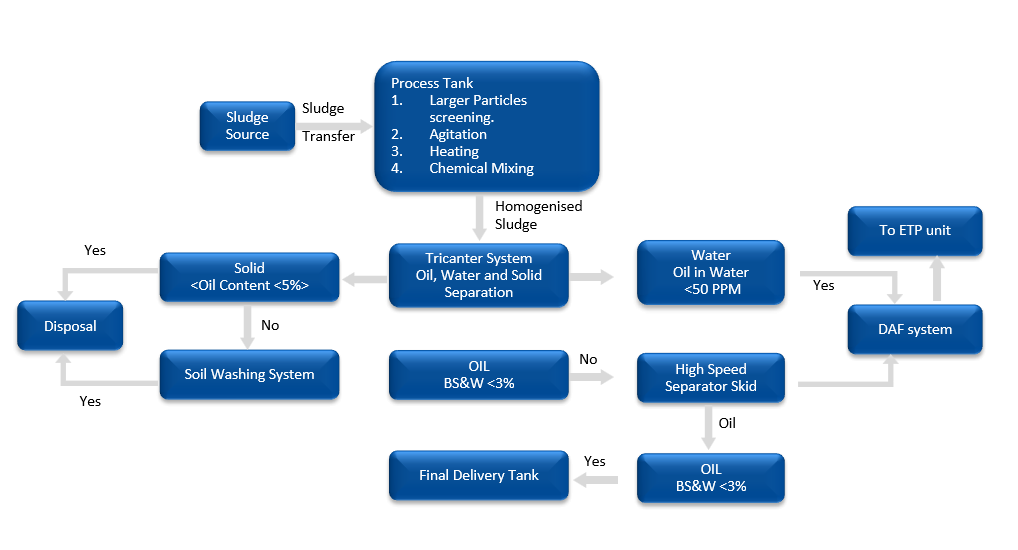

Crude Oil Sludge Treatment

Refinery Waste Treatment

Tank Bottom Treatment

Oil Recovery

ARSC51 SLOP

Drilling Slop Treatment

Drilling Mud Treatment

Oil Recovery

Oil Recovery

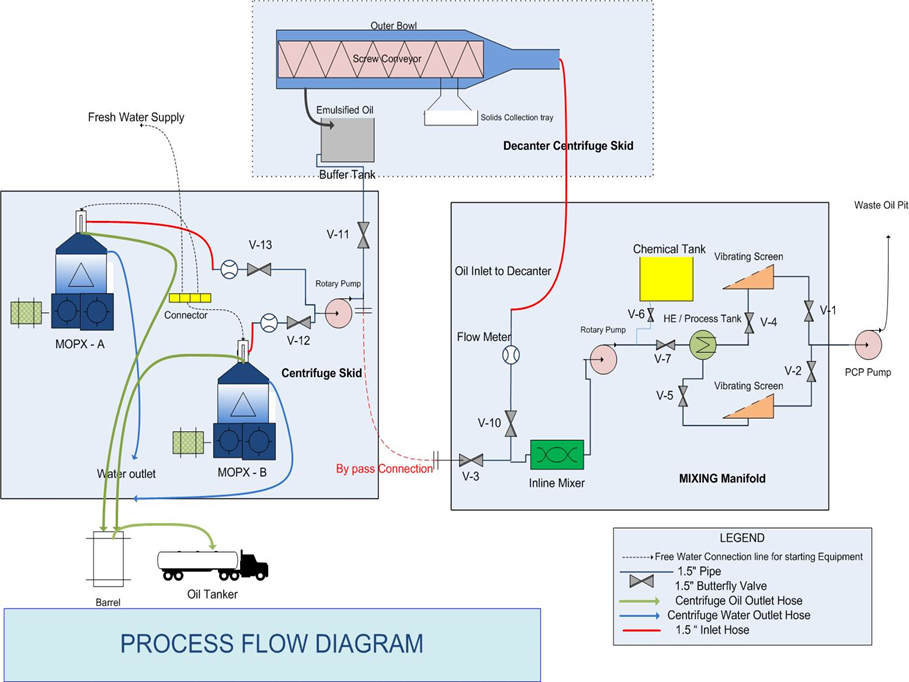

Vibrating Screen /Strainer

A 5 mm screen is attached to mainframe for screening

out the larger particles (leaves, sticks etc...).

Static Inline Mixer

A helical mixer in clear tubing for continuous mixing of fluids through loss of pressure.

Progressive Cavity Pump

Transfers fluid by means of progress, through pump,

of sequence of small, fixed shape, discrete cavities, as

its rotor is turned.

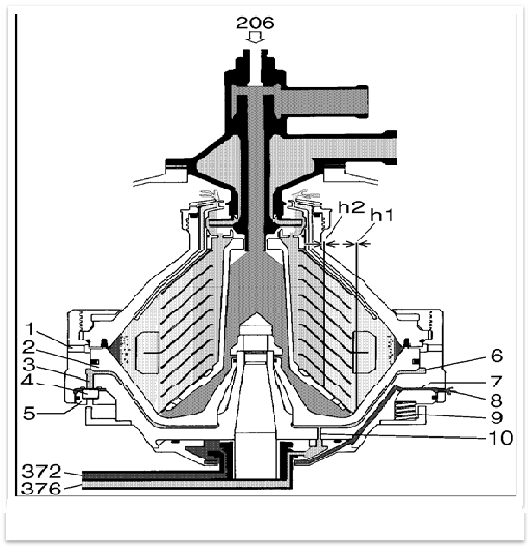

Decanter/ Tricanter Centrifuge :

Specially Designed Tricanter for Oily Sludge Processing (At Arham Oil Gas Workshop)

High Speed Separator (Centrifuge) :

Possible Application of Sludge/Waste Oil Processing Project in Your Area:

- 90-95% of the oil contained in the Sludge can be recovered as crude oil. Reusing this recovered crude oil as a valuable product for further refining process as raw material or as final product

- Separated solid is only approx. 10 - 20% of the original quantity of sludge as a result of significant reduction in transport, landfill costs

- Elimination of the environmental hazard

Engineering

- We are putting our Thousands of hours of Experience with the Products and Services we are providing to work for your next project.

- No learning curves. No Compromises.

- Our team of professionals and engineers with rich experience of operating under the demanding environment is committed to improve the Efficiency and Reliability of the Services which we Provides in Oil and Gas Sector.

Well Maintained

- Arham Oil Gas operates under challenging conditions and arduous schedules at every step, from exploration and production to transport, storage and processing.

- To ensure that the industry operates at optimal level with highest efficiency round-the-clock, We provides solutions on every step of the Services we are offering for the entire lifecycle of our Company.

Latest Equipments

- We are committed to provide our latest technology equipments and services for oil and gas production, refining processes.

- Some of them are designed and developed by our experts.

Safety Commitment

- Arham Oil Gas believes and works for safety and health to be values integrated in the routine of its employees. This assumption, stated in the Sustainable Development Charter of the Company, applies to all units where we are, that draw up strategies for the constant risk factors and runs several programs to protect its employees.

- We provide personal protective equipment (PPE) to our Engineers and Workers where engineering controls alone cannot protect workers from overexposure to chemicals, noise, or other hazards.

- We train our Engineers and workers to communicate with several Hazards.

Being a Services Provider, It is our responsibility to establish ways to protect workers, including developing and implementing safe practices for:

- Confined space; excavations

- Chemical handling; exposure

- Chemical storage

- Electrical work

- Emergency response

- Equipment/machine hazards

- Fire protection

- Hot work, welding, flame cutting operations

- Personal protective equipment use

- Power sources (lockout/tagout provisions, safe distance from power lines)

- Working in the heat, long shifts

FAQs

1What Is Sludge Oil Recovery And How Does It Work?

Sludge oil recovery involves extracting valuable hydrocarbons from oily sludge, a mix of oil, water, and solids, using mechanical separation (e.g., centrifuges), thermal desorption, and chemical treatment. Our integrated process recovers up to 95% of usable oil, reducing waste and maximizing resource value.

2What Types Of Sludge Can Be Treated?

Our systems handle a wide variety of sludge types from tank bottoms, skimmer oil, pigging operations, drilling fluids, and industrial effluents. We customize treatment steps such as centrifugation, chemical demulsification, and steam heating to optimize recovery based on sludge composition.

3How Much Oil Can Be Recovered And What Are The Economic Benefits?

Arham Oil routinely recovers 90–95% of hydrocarbons from processed sludge. Recovering oil not only offsets disposal costs and increases tank capacity but also generates direct revenue—especially when market prices are favorable.

4Is Sludge Oil Recovery Environmentally Safe?

Yes. Our method minimizes residual waste (solid fraction is <20%), limits pollution, and reduces landfill needs. Advanced treatment steps ensure compliance with global environmental regulations.

5Can Sludge Oil Recovery Be Performed On-Site With Mobile Units?

Absolutely. Our modular, mobile recovery setups, including tricanter centrifuges and steam-based LSPU units—can be deployed on-site, eliminating transport costs and achieving full processing within a few days.

6How Long Does Sludge Oil Recovery Usually Take?

Using mobile recovery units like tricanter centrifuges and steam-assisted systems, Arham Oil treats about 50–200 barrels (8–30 m³) per hour. In practice, a standard storage tank can be fully processed—including setup and breakdown, roboin under one week, while larger facilities may require 7–14 days total. This ensures swift, on-site recovery with minimal downtime.