Underground Drain Cleaning in Refinery — Ensuring Reliability, Safety & Environmental Compliance

November 7, 2025Arham Oil Expands Robotic Tank Cleaning Services Across the Middle East and GCC Countries

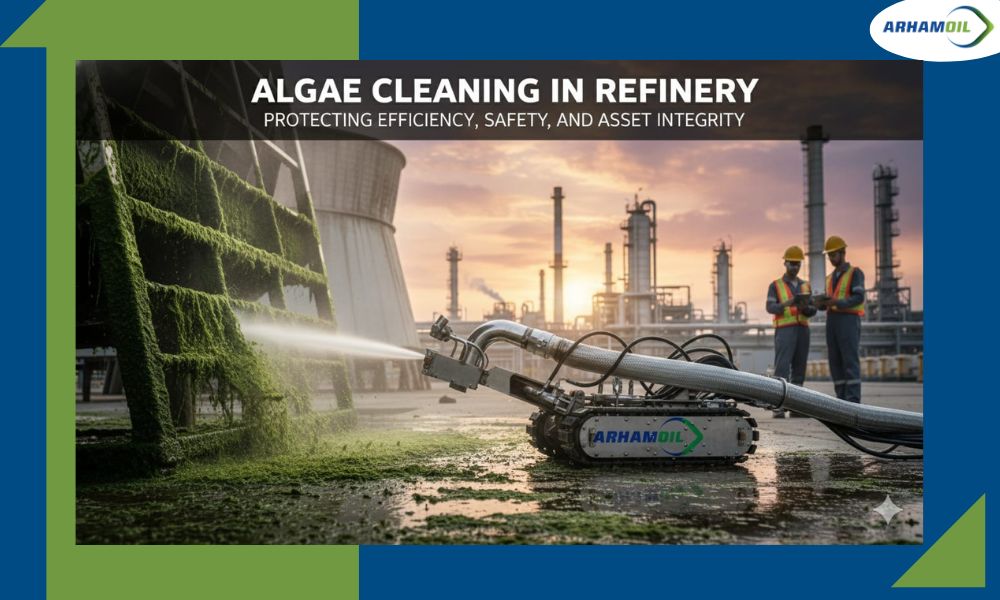

November 27, 2025Algae growth inside refineries has become a growing concern in recent years, especially in areas exposed to moisture, sunlight, hydrocarbon vapors, and stagnant water. While algae may seem harmless at first, it can severely impact refinery operations, cause corrosion, increase slip hazards, contaminate water systems, and interfere with essential equipment. For refineries that prioritize reliability and performance, professional algae cleaning is no longer optional, it is a critical maintenance requirement.

As an experienced oil and gas service company, we understand how biological growth affects refinery environments. Our cleaning solutions are designed to control algae, remove microbial contamination, and prevent regrowth while ensuring plant safety, environmental compliance, and uninterrupted production.

In this blog, we explain why algae develops in refinery areas, how it impacts plant performance, and why expert cleaning is essential for operational sustainability.

Understanding Algae Formation Inside Refineries

Refineries provide several conditions that encourage algae formation. Many operational zones involve water systems, cooling towers, exposed drainage areas, wastewater ponds, spill zones, and storage tank surroundings. These places accumulate moisture, hydrocarbons, dust, and sunlight conditions that allow algae to thrive.

One of the lesser-known contributors is hydrocarbon residue. When hydrocarbon vapors mix with moisture, they create a nutrient-rich surface where microbial colonies including algae can flourish. Over time, these colonies multiply and spread across floors, trenches, drain networks, water treatment units, pipelines, and open basins.

Algae also grows in effluent treatment plants (ETPs) and sludge ponds, where organic and inorganic wastes accumulate. Left untreated, algae creates thick biological layers that require specialized refinery algae cleaning services, not just manual scrubbing or chemical spraying.

Why Algae Cleaning Matters for Refinery Operations

Algae growth creates multiple challenges for refinery operations. It may appear as a cosmetic issue, but its effects go beyond aesthetics.

1. Operational Safety Risks

Algae forms slippery surfaces, especially around drains, walkways, and effluent areas. This significantly increases the risk of worker slips and falls, one of the most common industrial accidents. A single slip incident in a hazardous refinery environment can lead to serious injuries.

2. Corrosion and Asset Damage

When algae decomposes, it releases organic acids that accelerate corrosion on metal surfaces. This is a major issue for pipelines, drains, tank exteriors, and metallic structures that remain constantly moist.

3. Reduced Flow in Drainage Systems

Algae thrives inside trenches, stormwater drains, and wastewater channels. As it grows, it restricts flow and causes blockages that can lead to flooding, contamination, and hydrocarbon-water overflow.

4. Interference With Industrial Processes

Algae buildup in cooling towers or water circulation systems reduces heat transfer efficiency, increases energy consumption, and may even lead to equipment shutdowns.

5. Environmental and Regulatory Concerns

Refineries must meet strict wastewater and environmental discharge standards. Algae presence in ETP systems disrupts biological balance, causing compliance issues and potential legal consequences.

These factors make professional algae removal essential to refinery maintenance and long-term sustainability.

Where Algae Commonly Develops in Refineries

Algae can develop in multiple operational and non-operational zones inside refining facilities. Some of the most common hotspots include:

- Stormwater drains and underground drainage systems

- Cooling towers and water circulation lines

- Sludge ponds and wastewater storage areas

- ETP units and clarifier tanks

- Spill zones and hydrocarbon-contaminated floors

- Firewater ponds

- Storage tank external surfaces and bund walls

- Trenches and pipelines exposed to moisture

- Open basins and sumps

These areas require specialized algae cleaning techniques tailored to refinery environments, as traditional methods may not remove biofilm layers or prevent future microbial regrowth.

How Professional Algae Cleaning Is Done in Refineries

Effective algae cleaning involves multiple strategic steps. As a refinery-focused service provider, we use safe, systematic, and industry-approved methods to completely eliminate algae and prevent recurrence.

1. Site Assessment and Severity Mapping

Before cleaning begins, refinery zones are surveyed to identify the specific type of biological growth, its thickness, and its impact on operational systems. Mapping helps determine the right cleaning methodology.

2. Mechanical and High-Pressure Removal

For hardened algae layers, mechanical scrubbing or high-pressure hydroblasting is used to break the surface adhesion. This ensures complete removal of the visible layer and prepares the surface for deeper treatment.

3. Biofilm Breakdown and Surface Treatment

Algae tends to form strong biofilms that regenerate quickly if not fully treated. Specialized refinery-safe biological cleaners and chemical agents are used to break down these biofilms without damaging metal or concrete surfaces.

4. Drain and Pipeline Flushing

Blocked drains and pipelines are flushed using targeted high-pressure systems. This restores flow capacity, prevents overflow issues, and ensures smooth wastewater movement.

5. Sludge Extraction for Ponds and Basins

In sludge ponds, algae mixes with hydrocarbons and sediment. Advanced sludge treatment methods such as robotic desludging, mechanical pumping, and vacuum extraction are used for complete removal.

6. Anti-Regrowth Treatment

After cleaning, surfaces are treated with anti-microbial agents to prevent immediate algae regrowth and maintain refinery hygiene for long periods.

7. Environmental Compliance & Waste Disposal

All collected waste algae, sludge, water residues is processed using environmentally responsible disposal methods as per refinery waste management standards.

This streamlined approach ensures effective, safe, and long-lasting algae control in refinery environments.

Key Benefits of Professional Algae Cleaning in Refineries

Professional algae cleaning is not just a maintenance task it is a critical operational requirement. Some of the biggest benefits include:

- Enhanced worker safety through slip risk elimination

- Improved drainage performance, preventing flooding and blockages

- Reduced corrosion, extending asset life

- Operational efficiency in water-based systems such as cooling towers

- Better environmental compliance

- Cleaner refinery work environment, improving worker satisfaction and plant reputation

- Long-term prevention of algae regrowth

By ensuring that algae does not compromise refinery infrastructure, safety, or processes, refineries can maintain uninterrupted production and avoid costly repairs.

Why Choose a Professional Oil & Gas Company for Algae Cleaning

Refinery environments are sensitive, hazardous, and governed by strict safety standards. Algae cleaning in such facilities cannot be handled with general-purpose cleaning methods. It requires:

- Trained manpower

- Hazard-aware cleaning methodologies

- Industry-specific chemicals

- Knowledge of hydrocarbon behavior

- Deep refinery waste management experience

As a specialized oil and gas service provider, we offer algae cleaning techniques that integrate safety protocols, confined space entry rules, and refinery operational requirements. Our team ensures minimum disruption to plant operations, quick turnaround time, and long-term algae control.

Final Thoughts

Algae growth may start small, but in a refinery, its impact can be widespread and costly. From safety hazards to corrosion, inefficiency, and environmental risks, algae can compromise critical refinery systems. Regular professional algae cleaning helps protect assets, workers, and operational reliability.

If your refinery is experiencing algae buildup or requires preventive cleaning, now is the time to act. Keeping your facility clean is not just about appearance it is about safety, compliance, and operational excellence.

Want to Keep Your Refinery Safe, Clean, and Efficient?

Get in touch with our refinery maintenance experts today.

We provide advanced algae cleaning, sludge removal, oil tank cleaning, wastewater treatment, and complete refinery hygiene solutions designed for maximum safety and performance.

Frequently Asked Questions (FAQs)

1. How often should a refinery schedule algae cleaning services?

Most refineries schedule algae cleaning quarterly or biannually depending on climate, water exposure, and operational activities.

2. Can algae affect hydrocarbon product quality?

Yes, if algae enters water or storage systems, it may contaminate process fluid pathways, affecting overall product integrity.

3. Is algae cleaning required during monsoon seasons?

Yes, algae grows rapidly during wet weather, so monsoon-preparedness cleaning is highly recommended.

4. What chemicals are used for algae removal?

Refineries typically use industry-approved, biodegradable, and non-corrosive anti-algal formulations to protect structural integrity.

5. Can algae damage concrete structures in refineries?

Yes, algae produces acids during decomposition, which can slowly weaken concrete and cause surface pitting.