Arham Oil Expands Robotic Tank Cleaning Services Across the Middle East and GCC Countries

November 27, 2025Robotic Blasting & Painting: Safer, Smarter Surface Protection for Industrial Assets

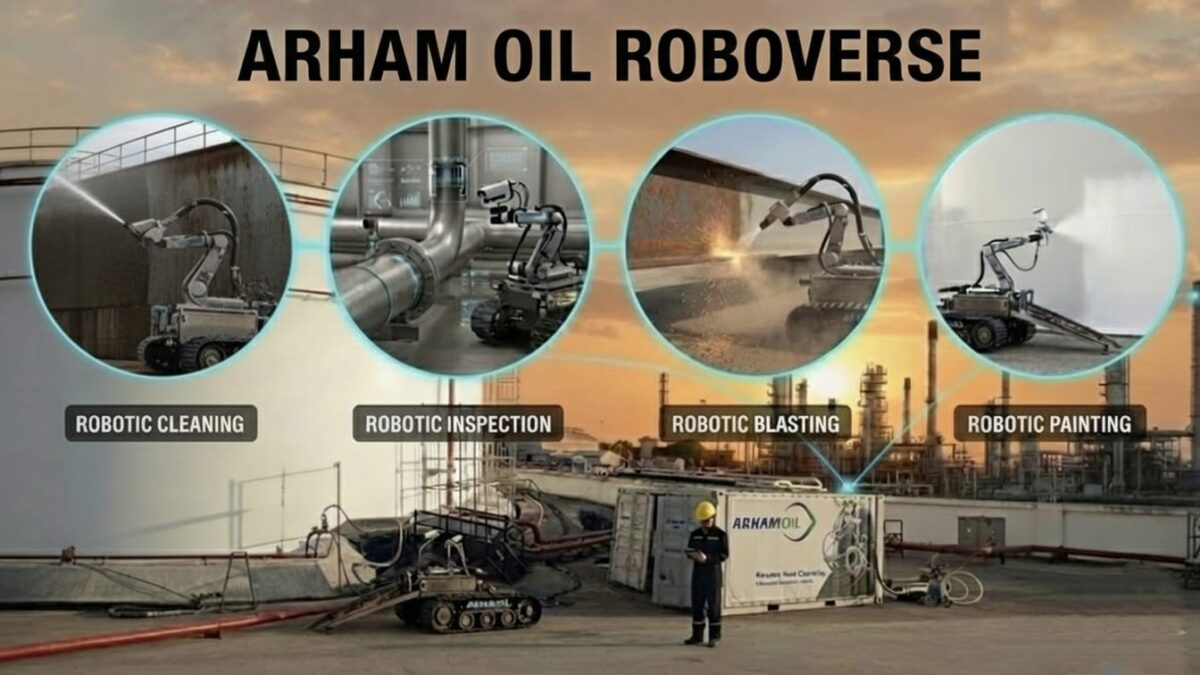

December 26, 2025Old plants, hazardous environments, growing sludge masses, and reduced turnaround cycles have made it impracticable for the traditional maintenance approach. This is where Robo Verse a complete ecosystem for robotic solutions—transforms the processes of inspection, cleaning, blasting, painting, and oil extraction in the refinery.

In Arham Oil, RoboVerse is a radical transformation from a rectification approach to maintenance to intelligent, automated, and riskless refinery operations. Rather than fixing issues one by one, RoboVerse combines various robotic solutions into a single offering for all major issues at the refinery, right from internal storage tanks to steel structures and waste retrieval systems.

Understanding Robo Verse in Refinery Operations

Robo Verse is not a single machine or service. It is a coordinated robotic ecosystem designed to perform multiple refinery maintenance and cleaning tasks with minimal human exposure. By combining robotic tank cleaning, robotic inspection, robotic blasting and painting, and oil recovery and processing services, Robo Verse delivers a complete lifecycle solution for refinery assets.

The core objective is simple: eliminate hazardous manual intervention while improving precision, consistency, and operational efficiency. Each robotic system within Robo Verse is designed to work independently or as part of a larger maintenance strategy, depending on the refinery’s operational needs.

Why Refineries Are Shifting Toward Robo Verse Solutions

Robo Verse is not a single robot or a single service offering. Robo Verse is a robotic ecosystem that has been designed to undertake various maintenance and cleaning activities in the refinery with least human intervention. By offering robotic tank cleaning, inspection, blasting and painting, and oil recovery and processing, the company offers a complete solution for refinery.

The eventual goal is straightforward: reduce dangerous manual intervention and enhance accuracy, reproducibility, and performance. Every robot solution in the realm of the Robo Verse can function alone or in conjunction with comprehensive maintenance programs, depending on refiners’ requirements.

Robo Verse Robotic Solutions for Refinery Key drivers:

- Prevention of human entry into dangerous and confined areas

- Minimized turnaround time during shutdowns

- Enhanced adherence to safety and environmental regulations

- Enhanced recovery of valuable hydrocarbons from waste streams

By integrating robotics across multiple functions, refineries gain operational continuity and long-term asset reliability.

Robotic Tank Cleaning: Safe and Efficient Internal Tank Maintenance

Storage tanks accumulate sludge, sediments, waxes, and hydrocarbon residues over a period of time. Cleaning the tanks manually puts workers at risk of being exposed to dangerous environments such as toxic gas, flammable vapors, and low oxygen.

The cleaning equipment for the tanks is robot-based. This means that the robot works automatically in the tank without human intervention. The robot is equipped with cleaning nozzles and has the ability to agitate the sludge. The cleaning equipment also has oil recovery units. These units are capable of recovering the hydrocarbon from the sludge.

This approach ensures:

- Zero confined space entry

- Rapid tank turns-around

- Enhanced safety compliance

- Maximum oil recovery from sludge

Robotic tank cleaning also enables continuous monitoring of internal tank conditions, helping refineries plan maintenance more proactively.

Robotic Inspection: Data-Driven Asset Integrity Management

Robotic inspection plays a vital role in Robo Verse by providing accurate, real-time insights into asset condition. Traditional inspection methods often require scaffolding, rope access, or shutdowns, limiting inspection frequency and data quality.

Robotic inspection systems equipped with high-resolution cameras, ultrasonic testing tools, and thickness measurement sensors can inspect tanks, pipelines, columns, and structural steel without interrupting operations. These robots navigate confined spaces, vertical surfaces, and submerged environments while transmitting live data to inspection teams.

Advantages of robotic inspection include:

- Detection of corrosion and structural damage early on

- Decreased downtime during inspection

- Enhanced Accuracy and Repeatability

- Digital Inspection Records – For Compliance and Audits

By integrating inspection data into maintenance planning, Robo Verse enables predictive maintenance rather than reactive repairs.

Robotic Blasting & Painting: Precision Surface Protection

“Surface protection is of the utmost importance for assets that could be corroded by chemicals, temperatures, or other aggressive factors. At Robo Verse, robotic blasting and painting operations allow for uniform surface treatment and coating application without involving humans in abrasive processes or toxic fumes.”

Robotic blasting systems are capable of removing corrosion, scales, and existing paints effectively, while preserving a smooth surface profile. Painting robots can also apply protective layers with a degree of precision that may be impossible to achieve with human labor, especially where main refinery structures are involved.

Robotic blasting and painting delivers:

- Uniform coating thickness and adhesion

- Reduced coating failures and rework

- Minimal environmental contamination

- Safer execution in elevated and confined areas

These systems are particularly effective for tanks, pipelines, pipe racks, and structural steel components.

Oil Recovery and Processing Services: Turning Waste into Value

A defining feature of Robo Verse is its integration of oil recovery and processing services. Refineries generate large volumes of oily sludge, slop oil, and contaminated wastewater during operations and maintenance activities. Improper handling of this waste leads to environmental risks and lost resources.

Robo Verse incorporates advanced oil recovery technologies such as centrifugation, thermal treatment, and mechanical separation to extract recoverable hydrocarbons from waste streams. The recovered oil can be reused or reprocessed, while the remaining solids are treated for safe disposal.

This approach provides:

- Maximum recovery of usable hydrocarbons

- Reduced waste disposal costs

- Improved environmental compliance

- Lower overall refinery operating costs

Oil recovery transforms waste management from a cost center into a value-generating process.

How Robo Verse Works as an Integrated System

The true strength of Robo Verse lies in its integration. Robotic inspection identifies problem areas, robotic cleaning removes contaminants, robotic blasting and painting restore surface integrity, and oil recovery systems process waste efficiently. Each component feeds data into the next, creating a closed-loop maintenance ecosystem.

This integrated workflow reduces redundancy, shortens maintenance cycles, and improves overall refinery reliability. Facility managers gain better visibility into asset condition, while procurement teams benefit from predictable project timelines and measurable outcomes.

Safety, Compliance, and Sustainability at the Core

Robo Verse is built around safety and sustainability. By minimizing human exposure to hazardous environments, it significantly reduces the risk of accidents and health issues. Automated processes also ensure compliance with international safety and environmental standards.

From a sustainability perspective, reduced waste generation, controlled emissions, and resource recovery align Robo Verse with modern ESG goals. Refineries adopting robotic solutions are better positioned to meet regulatory expectations and stakeholder demands.

Why Arham Oil’s Robo Verse Stands Out

Arham Oil brings deep industry experience and technical expertise to every Robo Verse deployment. Our understanding of refinery operations allows us to tailor robotic solutions to specific site challenges rather than applying generic automation.

We focus on:

- Custom-engineered robotic solutions

- Strict safety and quality controls

- Transparent reporting and documentation

- Long-term partnership approach

Our goal is not just to solve immediate problems but to help refineries build resilient, future-ready operations.

Conclusion: The Future of Refinery Maintenance Is Robotic

Future of Refinery Maintenance Is Robotics Robo Verse is the future of refinery maintenance a smart, integrated solution that will replace dangerous manual methods with high-precision robotic technology. It provides safety, efficiency, and sustainability to refineries through one integrated system that encompasses robotic tank cleansing, inspections, blast and paint, and oil recovery. Refineries wanting to improve their modernization processes while lessening risks and enhancing their asset performance can benefit immensely by taking the Robo Verse route. By becoming a part of Arham Oil, robotics developments will no longer remain just a dream but become a reality.