Sludge Pond Desilting: Restoring Efficiency and Environmental Balance in Oil & Gas Operations

October 21, 2025Algae Cleaning in Refinery: Protecting Efficiency, Safety, and Asset Integrity

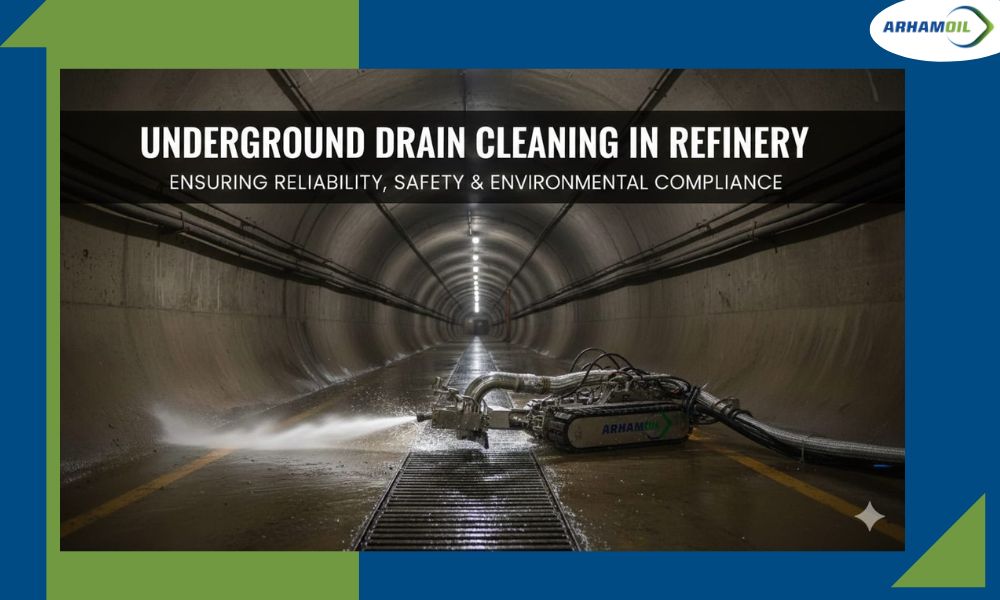

November 17, 2025Underground drain cleaning in refineries is one of the most critical maintenance operations because it directly supports plant safety, operational efficiency, and environmental compliance. Refineries depend on a complex network of underground drains designed to manage wastewater, contaminated liquids, stormwater, hydrocarbons, chemical residues, and accidental spills. When these drains become clogged or overloaded with sludge, scale, sediments, or oil residues, it can disrupt the entire facility’s drainage network, leading to flooding, corrosion, contamination risks, and unplanned shutdowns. This is why refineries consistently rely on professional underground drain cleaning services to maintain the system’s integrity and protect operational continuity.

As an Oil & Gas service company specializing in refinery maintenance, we understand how vital it is to keep these systems running smoothly. Our approach focuses on safe cleaning practices, high-efficiency tools, confined-space safety standards, and industry-approved technologies. With decades of experience, we ensure that underground drain cleaning is carried out with precision and care, providing refineries with reliable, long-term solutions.

Why Underground Drain Cleaning Is Essential in Refineries

Underground drains are responsible for transporting oily wastewater, rainwater runoff, chemical effluents, and various contaminated liquids to treatment facilities. Over time, these drains accumulate sludge, scale deposits, silt, sediment build-up, rust flakes, oil residues, and other waste materials. If not cleaned regularly, these contaminants create blockages that can affect the entire refinery.

Clogged drains cause water stagnation, backflow, corrosion, leaks, increased pressure on pipelines, and even potential environmental hazards. In more severe situations, blocked underground drains can force shutdowns or require emergency interventions. Preventive maintenance, therefore, becomes essential to avoid operational losses and unnecessary disruptions.

1. How Refineries Typically Manage Underground Drain Systems

Refineries usually operate a well-structured drainage network that includes oily water drains, stormwater drains, sewer drains, culverts, catch basins, sumps, and underground pipelines that connect different units to central collection systems. These networks are designed to quickly channel water and contaminants safely away from process areas. To keep the system functional, refineries follow a few core management practices.

First, a routine inspection schedule is created to monitor drain conditions using tools such as CCTV crawler cameras, hydrostatic testing, and manual inspection points. These inspections help identify early signs of blockage, corrosion, sediment build-up, or structural failures. Second, refineries maintain continuous monitoring of flow behavior, where flow meters, visual indicators, and pressure readings are used to detect abnormalities within the network.

Third, refineries rely on preventive maintenance by periodically flushing the system using water jetting, desilting machines, or vacuum suction units to remove accumulated sludge and debris before they become major problems. They also maintain proper segregation systems to separate oily water from clean stormwater, minimizing contamination risks.

Additionally, refineries document every cleaning or maintenance activity to comply with environmental regulations. This includes tracking the types of waste removed, the locations cleaned, and methods used. Finally, refinery safety teams ensure that all underground drain cleaning activities follow strict confined-space entry procedures, atmospheric testing, gas monitoring, PPE usage, and rescue preparedness to protect workers and maintain operational safety.

Common Causes of Blockages in Refinery Underground Drains

Blockages in underground refinery drains can be caused by sludge build-up, corrosion flakes, sand, soil, stormwater sediments, operational residues, oil deposits, scale formation, and foreign materials entering the drainage system. These materials gradually restrict flow and lead to structural issues. Identifying and addressing these early prevents major disruptions and regulatory concerns.

2. Key Benefits of Professional Underground Drain Cleaning in Refineries

Hiring a specialized industrial cleaning team ensures that underground drains are cleaned safely, thoroughly, and with advanced tools designed specifically for refinery operations. One of the biggest advantages is operational reliability clean drains allow wastewater and stormwater to move smoothly, preventing backups that could disrupt plant operations or damage equipment.

Professional cleaning also ensures improved safety, reducing the risk of hazardous gas accumulation, overflow of contaminated water, or potential fire hazards caused by hydrocarbon residues in drains. Teams trained in confined-space management, atmospheric monitoring, and refinery-specific protocols ensure that the entire process is conducted under safe conditions.

Another significant benefit is compliance with environmental regulations. Refineries must meet strict standards for water discharge, waste management, and contamination control. Professional services ensure all waste is properly removed, transported, and disposed of according to legal requirements.

Additionally, professional underground drain cleaning helps extend the life of pipelines and drainage structures by removing corrosive materials, sediments, and debris that can degrade the system over time. It also provides cost savings, as preventive cleaning is far less expensive than emergency repairs, system replacement, or shutdown-related losses.

Finally, specialized equipment such as high-pressure jetting units, vacuum trucks, robotic inspection systems, and sludge extraction machines ensure a faster, safer, and more efficient cleaning process compared to manual methods. Professional expertise guarantees that drains operate at peak performance, supporting overall refinery productivity.

Advanced Technologies Used in Modern Underground Drain Cleaning

Today’s cleaning methods include high-pressure hydro-jetting, suction and vacuum systems, robotic drain cleaning, CCTV inspection crawlers, sonar profiling equipment, root-cutting machines, and chemical flushing where required. These technologies allow cleaning teams to identify issues accurately, clean efficiently, and ensure minimal disruption to refinery operations.

Why Choose a Specialized Oil & Gas Service Company for Drain Cleaning

Refineries require partners who understand industrial safety standards, confined-space regulations, and hydrocarbon-handling protocols. A specialized Oil & Gas service provider brings the right combination of experience, certified technicians, refinery-approved equipment, and detailed SOPs to ensure reliable underground drain cleaning.

Working with an expert partner ensures the job is completed safely, on schedule, and in compliance with all environmental and operational requirements.

Conclusion

Underground drain cleaning in refineries is not optional—it is an essential maintenance activity that protects the entire facility’s safety, efficiency, and environmental integrity. With professional cleaning support, refineries can operate smoothly, avoid costly disruptions, and maintain compliance with industry regulations. Investing in reliable underground drain cleaning today ensures a safer and more efficient refinery tomorrow.

FAQs

1. How often should underground drains be cleaned in a refinery?

Most refineries schedule cleaning annually, but high-load areas may require more frequent maintenance.

2. What equipment is used to clean refinery underground drains?

Tools include high-pressure jetting units, vacuum trucks, CCTV inspection robots, and sludge removal systems.

3. Can underground drain cleaning be done during refinery operation?

Yes, with proper planning and safety controls, cleaning can be performed without shutting down the plant.

4. What happens if underground drains are not cleaned on time?

It can lead to flooding, contamination, corrosion, operational delays, and potential environmental penalties.

5. Does underground drain cleaning help with environmental compliance?

Absolutely. Proper cleaning ensures wastewater flows correctly and meets discharge standards.